The company is dedicated to excellence in merchandising, product development, production and logistics. We have earned a reputation in the global apparel industry as one of the foremost suppliers in Bangladesh for our commitment to quality, timely delivery, and total value. Through our extensive sourcing network, we have the ability to effectively procure the best product. Our customers rely on us to deliver the best quality products and superb service which enables them to successfully compete in the emerging market place.

Partnering for Quality and Ethics:

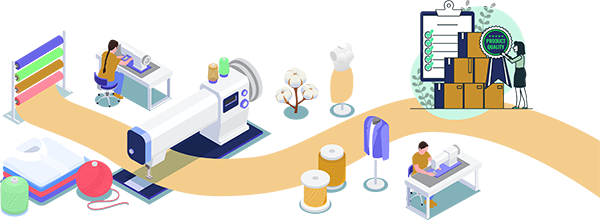

We partner with well-organized, vertically integrated factories that utilize state-of-the-art equipment for knitting, dyeing, sewing, printing, and embroidery. These facilities are certified against recognized ethical and quality standards, including WRAP and BSCI, ensuring social compliance and responsible manufacturing practices.

Our rigorous factory selection process considers product range, quality, capacity, facilities, management, technology, and workforce well-being. This ensures we source from partners who consistently deliver high-quality products while adhering to the highest ethical standards.

We have a strong supplier network and dedicated sourcing team who has continuous starving to ensure the right product at right cost from right place & at right time for this reason we are offering you competitive price from others with good quality goods.

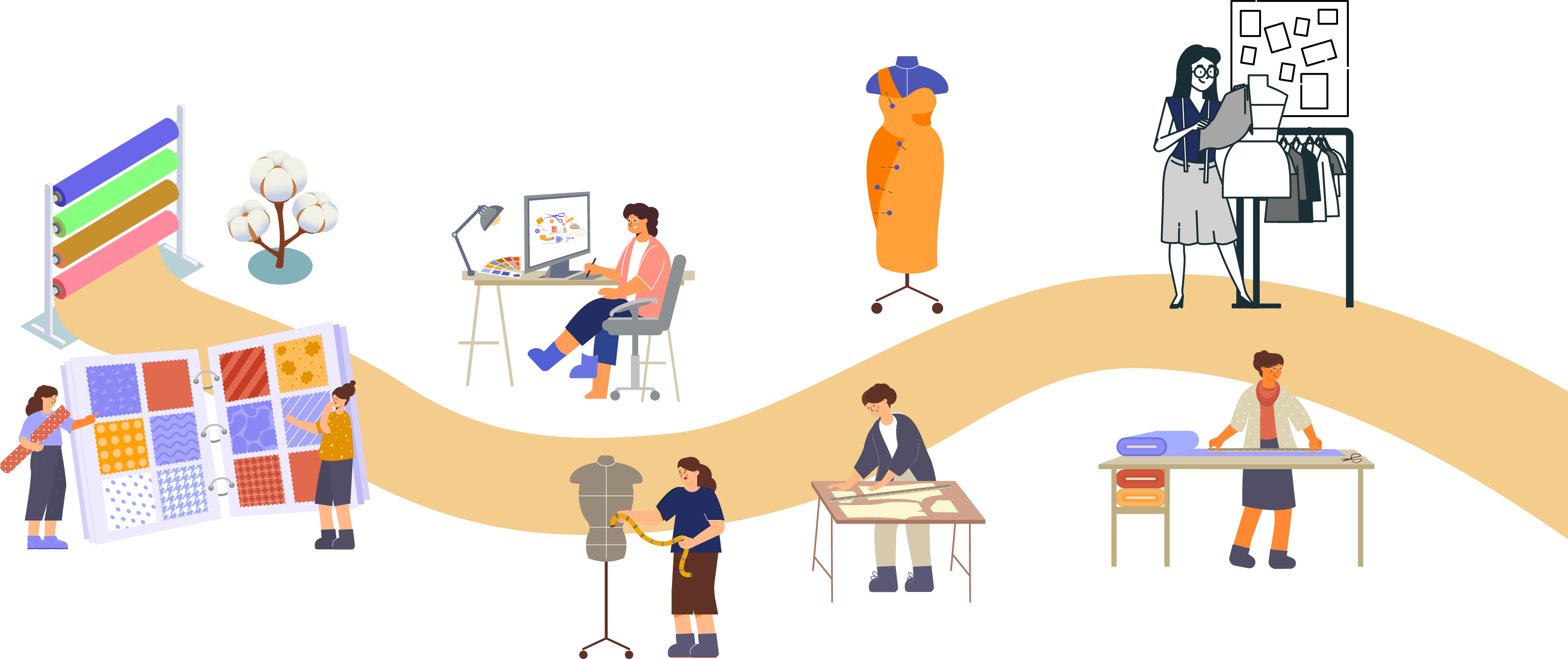

We have a research & development (R&D) Team with experienced designer, developer & technician. Also, we have in-house sample section facilities with senior machine operators and garment technicians. So, we can develop, cutting, stitching & finish samples instantly. if customer needs to customized any design & development then our R&D team cooperate with them & finalize design & development. We always focus new trend & technology.

Our Quality Assurance Policy is a concise and crucial document that outlines an organization’s commitment to maintaining and delivering top-notch products or services. It serves as a roadmap for maintaining consistent quality, defining standards and processes, and ensuring customer satisfaction. Key components include setting quality objectives, adhering to industry standards, outlining quality control procedures, assigning responsibilities. We have e dedicated Experienced quality & technical team. Our Quality Controllers visit the factory regularly to make sure we meet our buyer’s requirements. Our quality control personnel are stationed at all manufacturing sites to ensure that all production will meet according to buyer’s requirement. We always want to deliver satisfaction to our customers; we monitor the order from sourcing of raw materials and accessories to production and up to the final shipment of goods. We also monitor and report the status of the order to the buyer with systematic follow up on each and every stage.

Effective merchandising is central to our commitment to fulfilling your requests seamlessly. Each customer is assigned a dedicated team of experienced professionals who act as your single point of contact. Combining industry knowledge with extensive factory experience, our merchandisers possess a deep understanding of both your needs and production capabilities. This unique advantage allows us to bridge the gap, ensuring your vision translates into exceptional products that meet your specifications and excel in the market.

Quality means customer needs is to be satisfied, Quality management system is a number of measurements and techniques that are used to produce only quality goods in the first place with Zero defects. If the defects are occurring at all, corrective action must be taken to eliminate these effects in the initial stage for them to not reappear. We follow the AQL 1.5 to 2.5(As per buyer requirements). Our Quality Control is practiced right from the initial stage of sourcing raw materials to the stage of the final finished garment. We maximize the production of goods within these specified to clearances correctly the first time. We follow the AQL 1.5. Inspect all incoming, in-process & final goods to ensure quality of goods.

We understand the importance of offering competitive prices while maintaining product quality. We consider market trends, competitor pricing, and production costs to ensure you receive fair and valuable pricing for the products and services you require.

Supply chain management is a critical aspect of the garments manufacturing vendor’s operations, responsible for orchestrating the flow of materials, processes, and information from the sourcing of raw materials to the delivery of finished garments to customers. We have experienced supply chain team for smooth execution.

All shipping documents are reviewed and verified as per buyer instruction. All cargo is handled by reputable forwarder to obtain correct information regarding ETD and ETA of vessels because time delivery is as important for us as it is to the buyer.

2024 © All Rights Reserved For Bottomlite Tex

Developed by: EMBUNTECH